Inside the INSW Carbon Guidelines

Infrastructure NSW (INSW) has introduced a Technical Guidance for Embodied Carbon Measurement – a playbook to quantify the carbon footprint of materials in infrastructure projects. This guide helps engineers consistently measure “upfront” project emissions and pinpoint where to cut carbon.

Why Embodied Carbon Matters

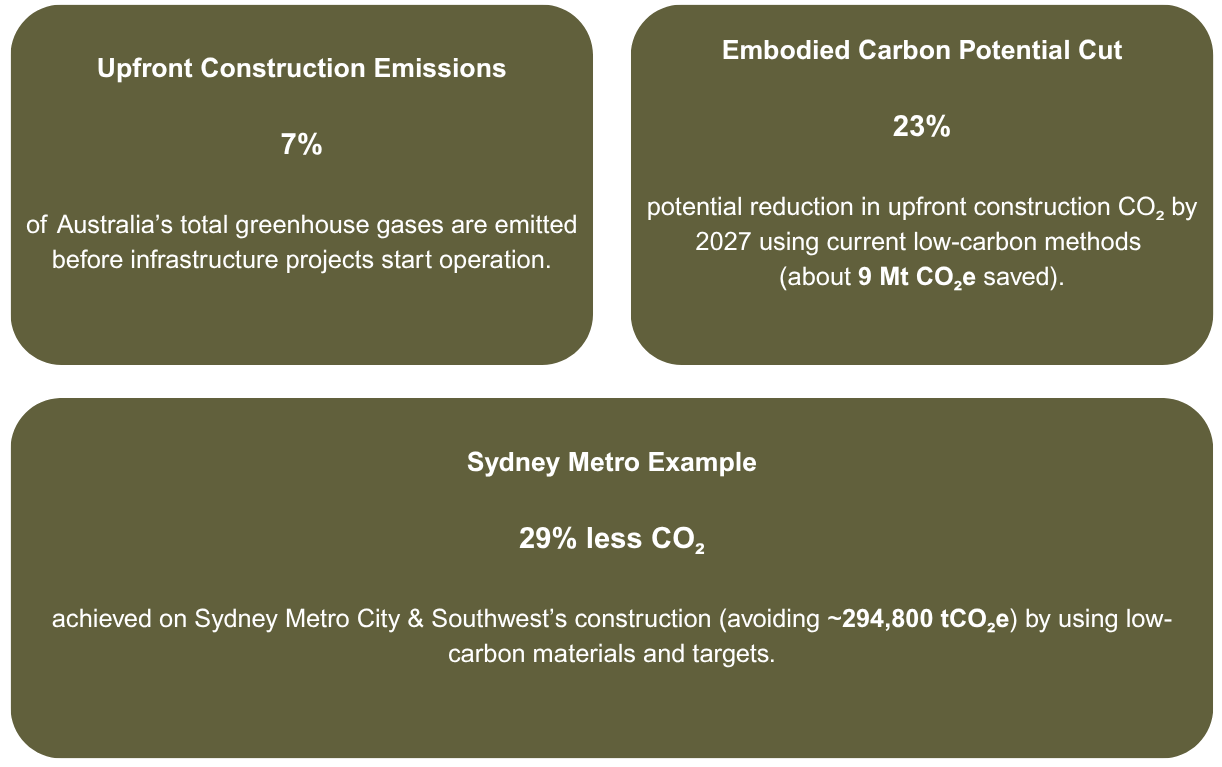

Modern infrastructure comes with a hidden carbon cost: the emissions from making concrete, steel, asphalt, and other materials, as well as construction processes. These embodied emissions are significant – the built environment (buildings and infrastructure) is responsible for nearly one-third of Australia’s total carbon emissions (over half if you include electricity generation). About 10% of Australia’s national CO₂ footprint comes just from the materials and construction phase. Crucially, roughly 7% of national emissions are “locked-in” before an asset even opens. Unlike operational emissions (which occur over a building’s life and can be improved later with green energy or retrofits), embodied emissions happen upfront and cannot be reversed once the project is built. Reducing them has an immediate climate benefit.

Understanding and managing these upfront emissions is now a priority. In April 2024, NSW introduced the Decarbonising Infrastructure Delivery Policy, which requires government projects to measure and report embodied carbon at key stages. The INSW Technical Guidance supports this by making sure everyone measures emissions the same way, with common data and methods. Consistent measurement means projects can be fairly compared and best practices shared. Essentially, the INSW Carbon Guidelines give infrastructure professionals a standard recipe to calculate a project’s carbon footprint from materials – so they can then work on cutting it.

What Are the INSW Carbon Guidelines?

The Embodied Carbon Measurement for Infrastructure – Technical Guidance is a document that outlines how to quantify the greenhouse gases associated with constructing infrastructure. It provides a common methodology for all NSW government infrastructure projects, so that a road and a hospital use the same basic approach to calculate emissions. Key points of the guidelines include:

Scope – What to Measure: Focus on upfront (embodied) carbon. This generally covers lifecycle stages from raw material extraction through manufacturing, transport, and construction (often termed “cradle-to-practical completion” emissions). Operational emissions (use-phase energy) are outside the primary scope, but the guide notes to be mindful of trade-offs (e.g. a design change that cuts construction emissions but raises operating emissions). The guide also defines what to include or exclude – for example, all major construction materials must be counted, while very minor items can be excluded for practicality.

When to Measure: Perform carbon assessments at three key stages of a project:

Stage 1 – Business Case / Early Planning: an initial estimate to inform option selection and baseline setting.

Stage 2 – Design & Procurement: a refined calculation during detailed design or before construction, using actual quantities and informing contractor requirements.

Stage 3 – Post-Construction (Practical Completion): a final as-built tally of emissions to report outcomes.

By measuring multiple times, the accuracy improves as the design solidifies, and it keeps carbon on the radar throughout project development.

How to Measure: The guide describes a step-by-step process:

Build a materials inventory: List the quantities of key materials (concrete, steel, etc.) and relevant construction inputs for the project. Early on, this might use high-level estimates; later it uses detailed bills of quantities.

Use standard emission factors: Multiply each quantity by an agreed emission factor (kg CO₂ per unit) to calculate emissions. INSW provides a standardized set of factors (the NSW Embodied Carbon Databook, drawn from industry data). Everyone using the same factors ensures apples-to-apples results. If project-specific data is available (e.g. a supplier provides an Environmental Product Declaration with a lower emission factor), that can be used – but defaults are there if not.

Sum up and report: Add all material emissions for the total embodied carbon figure (usually reported in tonnes CO₂e). Break the results down by material or asset component to see which parts dominate. The guidance includes templates for reporting at each stage, ensuring information like assumptions and data sources are documented consistently.

Tools and Data: The guidance doesn’t mandate a specific software tool – teams can use a spreadsheet, a lifecycle assessment (LCA) software, or other calculators – but it emphasizes using the same assumptions and data. An appendix lists recommended data sources and even a “worked example” of a carbon calculation. The main point is, whether you use a fancy tool or not, follow the common method in the guide so the outcome is reliable and comparable.

In short, the INSW Carbon Guidelines answer the questions: What do we measure? When do we measure it? How do we measure it? By adhering to them, infrastructure professionals can produce a credible carbon footprint for their project and be confident it aligns with what other projects are doing.

Using the Guidelines to Measure Emissions

For infrastructure professionals, using the INSW guidelines might look like this in practice:

Early Stage (Business Case): With only a concept design, you might say, “For this new bridge, roughly how much concrete and steel will it use?” Using reference projects or cost estimates, you come up with approximate quantities and then apply the standard emission factors. Maybe you estimate the bridge will cause ~50,000 tonnes CO₂e. You document this as the baseline embodied carbon for the preferred option. If you’re comparing options (say, a shorter span vs. a longer span), you’d estimate both to see which is lower carbon. At this stage, the numbers are coarse, but they highlight big differences and set the scene.

Design Stage: Now you have detailed plans. You know it’s, say, 10,000 m³ of concrete of type X, 2,000 tonnes of steel of grade Y, etc. You plug these into your carbon calculator with the official factors. Suppose it comes out that concrete accounts for 60% of the carbon and steel 30%. This insight is crucial: you might focus on finding a lower-carbon concrete mix, or slimmer design, to reduce that 60%. You could also set requirements for the contractor: e.g. use cement with 30% fly ash or procure Green Star certified steel, and include those in tender specs. The design-stage calculation might show you’ve reduced the footprint to 45,000 t CO₂e thanks to design improvements.

Construction Completion: After building the bridge, you gather the actual usage: maybe 9,800 m³ of concrete were used (a bit less than planned due to efficiencies) and 2,100 t of steel (slightly more due to some scope change). You also capture any other emissions like fuel used on site if required. Re-calc with these final numbers – say you get 47,000 t CO₂e. You compare this with the earlier estimate and note any deviation. This final report is submitted per policy, and it can be used to benchmark for future projects (“Bridge of X size = ~47 kt CO₂e, but we managed to beat the initial estimate by 6% through design and material choices!”).

By following the above process, infrastructure professionals create a carbon footprint that’s not just a one-time figure, but a management tool throughout the project. The act of measuring at each stage means teams are continually looking for ways to do better. This leads us to the next part – once you know your carbon hotspots from the measurements, how do you reduce them?

Finding Carbon Reduction Opportunities

The INSW guidelines go hand-in-hand with a Carbon Reduction Hierarchy approach – basically a priority list for cutting carbon. Here’s how infrastructure professionals can identify and implement reductions:

Build Smart, Build Less: The first step is to question if all that material or construction is even needed. Can the design be optimised to use less material (without compromising safety)? For example, refine the structural design to eliminate over-conservative margins, or use design alternatives that require fewer resources. If a section of pavement can be narrower or a retaining wall shorter while meeting requirements, those changes directly cut out tonnes of concrete or steel (and thus CO₂). The NSW policy explicitly encourages challenging the need and extent of new construction at business case stage – sometimes the greenest solution is a smaller project or an existing asset reuse.

Low-Carbon Materials: Identify materials with the biggest carbon impact (your measurement will show this). Then explore alternatives:

Use blended cement in concrete (replace part of clinker with fly ash, slag, etc.). This can cut concrete’s carbon footprint by 20-50% easily. The Sydney Metro project, for instance, used a concrete mix with 58% cement replacement in some areas.

Choose recycled or lower-emission steel. Many steel suppliers offer products with recycled content or made in electric arc furnaces, significantly reducing CO₂ per tonne.

Consider emerging materials: e.g., geopolymer concrete (cement-free) was used for railway sleepers in Sydney Metro, and recycled plastic or timber can sometimes substitute for concrete in non-structural elements.

Engage the Supply Chain: Contractors and suppliers often have innovative ideas when pushed. In procurement, ask bidders to propose low-carbon solutions or even make it a scored criterion. Set carbon targets in contracts (Sydney Metro set a 20% reduction target for its contractors) to embed accountability. Suppliers might come back with options like new mix designs, use of locally sourced materials (reducing transport emissions), or more efficient construction methods.

Waste Not: Reducing waste in construction means fewer materials need to be produced overall. Plan construction to avoid over-ordering and to reuse off-cuts. Also, use recycled aggregates or reclaimed materials where possible. Not only does this avoid emissions from producing new material, it often diverts waste from landfill. High recycling rates (90%+ of construction waste reused) were part of Sydney Metro’s strategy.

Innovate in Design and Method: Think outside the box for big wins. Maybe use prefabrication (which can reduce waste and allow better material control), or design modular components that can be disassembled and reused in the future (supporting a circular economy). Each project might have unique opportunities – like using the soil on site to make rammed earth walls instead of imported bricks, etc. The key is: once carbon is a metric, it spurs creative problem-solving across the team.

By targeting the major contributors revealed in the carbon assessment, engineers can systematically trim down the emissions. The results can be impressive – as noted earlier, a project like Sydney Metro City & Southwest achieved nearly a one-third reduction in embodied carbon through such measures. Even typical projects can often save 10-20% with diligent effort, and up to 20-30% if they really push innovation. These savings are achieved long before the first solar panel or wind turbine offsets operational energy; they’re baked into the project from the ground up.

QIA’s Carbon Management Planning Service

Tackling embodied carbon can be complex, but you don’t have to do it alone. Quantum Insights Advisory (QIA) offers a dedicated Carbon Planning service to help projects implement these guidelines and go beyond compliance. Our services include Carbon Management Planning, Embodied Carbon Assessments and Estimates, Carbon Value-Management, and Carbon Advisory. In practice, we work with your team to:

Quantify your project’s emissions using industry-aligned tools (fully consistent with INSW’s methodology).

Identify and evaluate reduction options – we bring knowledge of the latest low-carbon materials and techniques to find savings that make sense technically and financially (this is our “carbon value-management” approach).

Integrate carbon into project decisions – from setting carbon targets in the business case to embedding requirements in procurement, we guide you each step of the way.

Provide assurance – we can independently review and verify carbon calculations and sustainability claims, giving confidence to you and your stakeholders that the numbers are solid.

Our goal is to help you reduce the environmental impact of your asset in the most efficient, cost-effective way possible. We’ve helped clients use the INSW Carbon Guidelines to not just check a box, but to truly drive innovation and carbon reduction in their projects. Whether it’s developing a Carbon Management Plan for a new highway or conducting a carbon footprint audit for a rail extension, QIA’s expertise ensures you get the best sustainability outcome without sacrificing project goals.

Interested in cutting the carbon on your next infrastructure project? Reach out to QIA to learn how our carbon management planning services can support you – from strategy to implementation.